- Home

- Live Blog

- Breaking News

- Top Headlines

- Cities

- NE News

- Sentinel Media

- Sports

- Education

- Jobs

Dr Mukul Chandra Bora

(The writer is Director, Dibrugarh University Institute

of Engineering & Technology. He can be reached at drmukulcbora@gmail.com)

3D printing is one of the most vital technology of the Industrie 4.0 and it is the technology which will going to revolutionize the whole manufacturing process including construction. It is also called as additive manufacturing as it does not involve the process of cutting and also having the advantage of rapid prototyping of any products starting from small products to the products used for aviation industries. India is the 2nd largest populated country of the world out of which nearly 65% are belongs to youth and with the available industries it will be difficult to accommodate for any placement. The Government of India is working hard to make them self-employment and the 3D printing may be one of the viable alternative for the educated unemployed youth of the country. The primary objective of this work is to present how 3D Printing has evolved from a marginal technology to the stage of digital manufacturing and how the technology is going to impact the existing and future business models. The paper begins with an introduction and historical context of 3D printing and how it will going to change the entire manufacturing industries of the future. Here in this paper we are going to present how this technology may change the employment scenario of the country and how it will lead to the growth of MSME sector throughout the country.

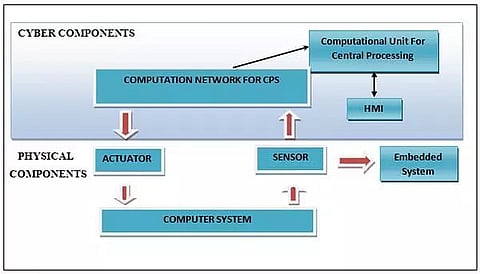

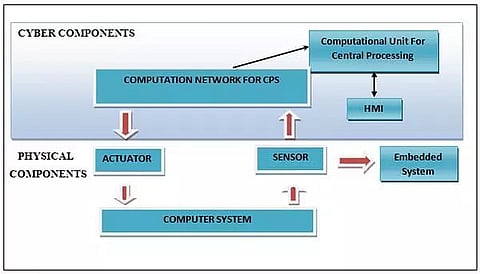

The manufacturing of goods has always been linked to societal developments. Industrialized processes of building and replicating goods have influenced social orders often culminating in the creation of new social constructs. In the past, different methods for fabrication have served artisans' wishes to solve day to day needs. Today, automation and mass-production has liberated a great part of the population, creating a large knowledge-based society and building the foundation of welfare society. Making a fast forward historical review, the second industrial revolution brought the division of labor and the reduction of marginal costs into the manufacturing of goods. The third industrial revolution came with the information age and automation. While society at large has benefited from economies of scale to create a large middle class society, the dominating models in the 19thand early 20thcentury have served us to construct the welfare state as we know it today. Finally we are now in the change towards the fourth industrial revolution, in which machines and humans will be connected in cyber physical systems (CPS) (A cyber-physical system (CPS) or intelligent system is a computer system in which a mechanism is controlled or monitored by computer-based algorithms. ... Examples of CPS include smart grid, autonomous automobile systems, medical monitoring, industrial control systems, robotics systems, and automatic pilot avionics).

Figure 1.

3D printing (not a printing technology as such) is a word which is more frequently used by almost each and every person of our society especially after the outbreak of COVID-19 pandemic in India. It is the 21st century skills which will revolutionize the entire manufacturing industries. But using some technical terms without understanding its brief details is somewhat not proper for the educated people of our society which are used to read and watch media, both print and electronic media. So it is wise to highlight some basic concepts for the understanding of 3D printing its uses and relevance in our day to day life. Manufacturing of components and goods from metals are primarily done through two different processes known as Subtractive Manufacturing and Additive manufacturing except the methods of molding. Subtractive manufacturing may be defined as processes in which material (usually metal) is removed from a crudely-shaped initial part (perhaps a bar or slab, or a forging or casting with a more complex shape) to achieve the final shape and dimensions and are very widely used in manufacturing. Lathe-turning, milling, drilling, sawing, thread-cutting and gear-cutting are some examples of subtractive processes involving metal-cutting that are traditionally carried out in specialized machines. The modern trend is toward integration of several processes into a single machining centre under digital control, in which loading and unloading of the work piece is avoided between the individual sequential steps. On the other hand, additive manufacturing is a process that adds successive layers of material to create an object and is often referred to as 3D printing and as the name suggests it the opposite of additive manufacturing. So the 3D printing may be defined as:

A method of manufacturing known as 'Additive manufacturing', due to the fact that instead of removing material to create a part, the process adds material in successive patterns to create the desired shape. The primary use of 3D printing may be summarized as below:

v Prototyping

v Specialized parts – aerospace, military, biomedical engineering, dental

v Hobbies and home use

v Future applications– medical (body parts), buildings and cars

The history of 3D printing technologies was way back to late 1980's and was called as Rapid Prototyping (RP) technologies as this process of manufacturing was originally conceived as a fast and cost-effective method for creating prototypes for product by the manufacturing industries. The first patent application of RP technology (later known as 3D printing) was filed by a Dr. Kodama of Japan in May 1980 and due to non-filling of the full patent specification within one year of the application and hence rejected and just became a history now although he was a patent lawyer. Just after the innovation of rapid prototyping methods in the year 1980, many experiments were made and different 3D printing processes were created from 1980-1988 and the following are persons which has bring this incredible innovation to the mankind which is helping a lot during this period of crisis of COVID-19. It is well understood that those innovators had created a revolutionary process in manufacturing industry but it was not known to them that this technology is going to evolve and prompt profound transformation in the whole manufacturing world during this period of pandemic. Let us find out the history of 3D printer.

1980: First patent by Japanese Dr. Kodama for Rapid Prototyping (Japanese Doctor)

1984: Stereo lithography by French then abandoned

1986: Stereo lithography taken up by Charles Hull, founder of 3D Systems

1988: Carl Deckard brought a patent for the Selective Laser Sintering (SLS) technology,

1988: Scott Crump, a co-founder of Stratasy's Inc. filed a patent for Fused Deposition Modelling (FDM)

The real invention of 3D printing was first formally undertaken by Charles W. Hull in the year of 1983 and he has created the first 3D printer component in the same year in the world. It was the Hull who used got his US patent application in the year 1984 for "Apparatus for production of three-dimensional objects by Stereo Lithography" andthe U.S. patent US4575330 was granted in the year 1986. Due to the development in computer programming and hardware, an advanced CAD/CAM/CAE software can mathematically slices the computer model of any object into a large number of thin layers or slices and this process may use to builds the object in layer by layer starting with the bottom layer and is a part of additive manufacturing. It was the year 1987 in which first 3D printer i.e., the Stereo Lithography (SLA) printer comes to the market and the same is now widely used in rapid prototyping and direct manufacturing. A few years later, Scott Crump invented fused deposition modeling (FDM), another 3D printing technology in the year 1988 and nearly after twenty years of invention of 3D printing technology quietly evolved and developed, and was utilized mostly by designers and engineers in the business world throughout the globe. The real journey of 3D printing technology has started in 2005 with the advent of the Rep Rap project of Dr. Gordon and become open source with the goal of making 3D printing technologies accessible to all. It was the year 2009 when Bre Pettis, Adam Mayer, and Zach Hoeken Smith decided to market this technology to consumers and in they founded Maker Bot (Maker Bot Industries, LLC is an American desktop 3D printer manufacturer company headquartered in New York City) in 2009 and brought one of the first full assembled and customer friendly 3D printers and it leads to awareness in the consumer market and become the "future technology/skill" and is a matter of discussion amongst the industry analysts, stock watchers, and mainstream media as well as amongst the academia in the whole world.

The 3D printing machine developed in 1980's is now run on software that slices the Computer Aided Design 3D model into different layers of slices and those layers are then traced onto the build plate by the printer. The conventional manufacturing techniques which is also known as 'Subtractive Manufacturing', in which materials are removed from a predetermined block of metals. The method of subtractive manufacturing results in lot of waste as the material that is cut off generally cannot be used for anything else and become scrap and 3D Printing eliminates such waste since the material is placed in the location that it is needed only, the rest will be left out as empty space.

Current and Future applications of 3D Printing:

Biomedical Engineering

The invention of 3D printing technology has enabling us to create human body parts and parts of organs as per patients specific and first entire organ created through 3D Printing is expected to be done in the coming years. The process of creating the organ or body part is exactly the same as that of plastic or metal part, however but in this case the raw material used are biological cells created in a laboratories and thereby helps the Biomedical Engineers to create cells for a specific patient which ascertain us non rejection of that parts by the patient's body. Orthopedic application of 3D printing enable us to create limbs and other body parts out of metal or other materials to replace lost or damaged limbs. Prosthetic limbs are of huge need in and around the world due to injuries sustained during war or by disease and are very expensive as well as not customized for the patient's needs. 3D printing is being used to design and produce custom prosthetic limbs to meet the patient's exact requirements with the help of scanning the patient's body and existing bone structure, designers and engineers are able to re-create the lost part of that limb.

Aerospace and Automobile Manufacturing

The manufacturing companies which need high level of accuracy and precision such as aerospace and automobile sectors have been using 3D printing as a prototyping tool and in recent years. This process of design and 3D printing has allowed these companies to advance their designs faster than before due to reduction in design cycle and substantially reduced their production time from months to hours. The future of 3D printing in these industries lies with creating working parts directly from a 3D printer for use in the final product. 3D printing has make it possible to create complex geometrical parts easily allowing for parts to be lighter, stronger than their machined counterparts.

Construction and Architecture

The Architects and city planners have been using 3D printers to create a model of the layout or shape of a building for many years and they are looking for ways of employing the 3D printing concept to create entire buildings. The goal is there to replace many cranes and even construction workers with these 3D printing technology and would work by using the 3D design model to create a layer by layer pattern on the building just as a normal 3D printer works today. Most of the innovation in this area will have to come from the creation of the appropriate materials.

Product Prototyping

The creation of a new product is always associated with many iterations of the same design and the invention of 3D Printing technology has entirely revolutionized the industry which allows the designers to create, see and touch their design which in turn reduces the several meetings for everyone to agree on one design to create. Nowadays a version of each idea is created and the next day, all are reviewed together, thus giving the ability to compare and contrast each one's features.

The 3D printing industry has grown very fast over the past few years and sectors like aeronautics, engineering, fashion design, education, healthcare and fast-moving consumer goods (FMCG) have already started adapting 3D printing in their production process. According to a research by Global Market Insights, the 3D printing material & equipment market in the Asia Pacific is predicted to witness high growth in the coming years, owing to the substantial growth of manufacturing in sectors like automotive and the rapid technological advancements. This surge in 3D printing will create a whole new category of new jobs and investment opportunities.

So by realising the potential of 3D Printing Technology, this area should be given high priority by the Organisation like CII, Industries and Commerce Department, MSME, and other Government and private agencies in India. This will not only create job and self-employment avenues but also help us to mitigate the problem of unemployment in India if taken this manufacturing technology in a mission mode. 3D printing business is a whole sector in industry, which already is very profitable and generates huge money, even thou it's still young and new on the market. ... Because market trends for 3D printing are very positive, 3D business has high probability of bringing you wealth and a lot of income. The cost of 3D Printing business may range from Rs.75, 000/- to Rs. 75, 00, 000/- depending upon the scale and types of machinery used for production and is impossible to be more precise because not only does "3D printing" cover a very wide range of technologies, machine costs and material overheads.